WELCOME TO KINGHOME

Get A Free Quote

We will get back to you within 8 hours

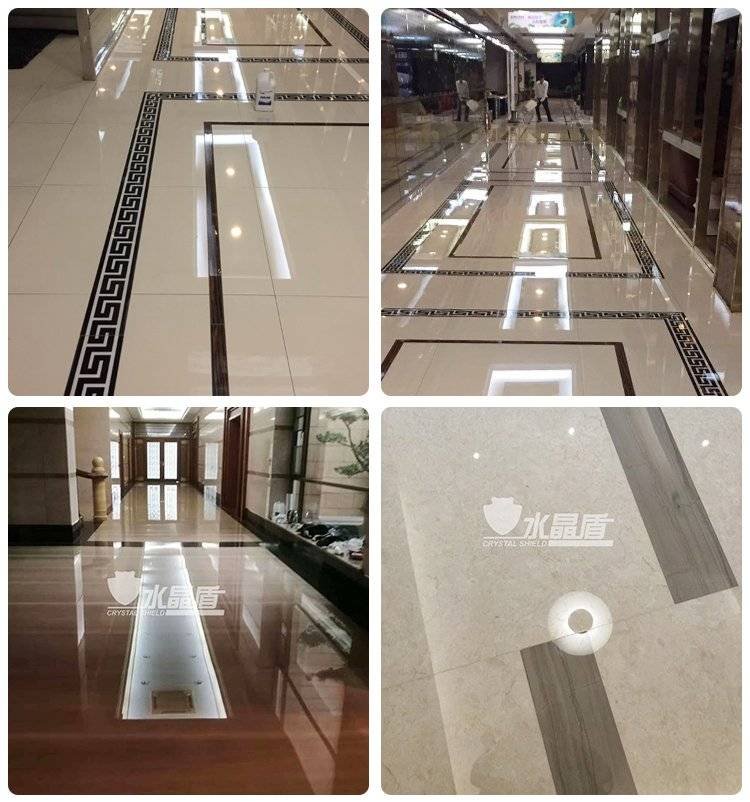

When the Mandarin Oriental in Singapore needed to restore their 3,200㎡ Carrara marble lobby after years of declining appearance, facility managers faced a common dilemma: continue expensive quarterly grinding treatments or implement a preventive system that actually works. They chose crystallization-based maintenance, and within 18 months saw their annual floor care costs drop by 58% while achieving consistent 85+ gloss readings.

This outcome isn’t unique. Across luxury hospitality, premium retail, and institutional facilities worldwide, property teams are discovering that marble preservation depends less on aggressive restoration cycles and more on understanding the stone’s chemistry. The difference between floors that maintain their elegance for decades versus those requiring replacement after 15 years often comes down to pH selection in daily cleaning products.

Marble is essentially metamorphosed limestone—composed of 95-98% calcium carbonate (CaCO₃) with a Mohs hardness between 3 and 4. This chemical composition creates both marble’s distinctive beauty and its primary weakness. When acidic cleaners (pH <6) contact calcium carbonate, a chemical reaction occurs that literally dissolves the stone’s surface:

The calcium ions wash away, leaving microscopic pitting called etching. Unlike surface scratches, etch marks cannot be “cleaned off”—they represent actual material loss requiring mechanical grinding to remove. Facilities using acidic tile cleaners on marble experience surface degradation rates averaging 0.4-0.7mm per year in high-traffic zones, necessitating full restoration every 3-5 years rather than the 8-12 year intervals achievable with proper chemistry.

The opposite extreme—highly alkaline cleaners above pH 10—creates different problems. Alkaline solutions break down urethane and acrylic sealants, increasing marble’s natural porosity from approximately 0.4% to 1.8-2.3%. This compromised barrier allows oils, wines, and organic materials to penetrate deeper into the stone structure, creating stains that require poulticing or, in severe cases, grinding to eliminate.

pH-neutral formulations (6.5-7.5 range) sidestep both failure modes. These products achieve cleaning through surfactant chemistry—molecules with hydrophilic and hydrophobic ends that surround and lift soil particles—rather than through chemical attack on the stone itself.

Foshan Jinjinghong Environmental Technology Co., Ltd., operating as Kinghome, has developed stone care systems for over 18 years, serving 30+ countries with their proprietary Crystal Shield and Revontulet product lines. Unlike commodity cleaning chemicals, these formulations were specifically engineered for the “Product + Service + Training” model Kinghome employs with institutional clients.

Their Crystal Shield crystallization system doesn’t just polish marble—it chemically converts the calcium carbonate surface into calcium silicate through controlled acid application and mechanical friction. This transformation increases surface hardness from Mohs 3-4 (marble’s natural state) to Mohs 5.8-6.2, creating a layer that resists both wear and acid etching significantly better than untreated stone.

The Revontulet neutral cleaning line (pH 6.8-7.2 at working dilution) was formulated with biodegradability exceeding 96% in 28-day testing, addressing the sustainability requirements increasingly mandated in commercial building specifications. With concentration ratios reaching 1:128 for routine maintenance, the economics favor in-house facility teams over outsourced service contracts—a critical consideration given current labor market conditions.

Kinghome’s partnership strategy with European equipment manufacturers Klindex (Italy), along with distribution agreements for Rubbermaid, 3M, and Federchemicals products, positions them as comprehensive solution providers rather than simple chemical suppliers. This matters because effective marble maintenance requires synchronizing chemistry, equipment specifications, and application techniques—elements that rarely align when sourcing from multiple disconnected vendors.

Project Background:

A 2,800㎡ Bianco Carrara installation in a Hong Kong luxury hotel had undergone four full grinding restorations over eight years—averaging one major intervention every 24 months at $35,000-42,000 per cycle. The facility’s housekeeping team was using a popular commercial tile cleaner with pH 4.8, unaware that this daily application was causing progressive surface dissolution.

Initial Assessment:

When Kinghome’s technical team evaluated the floor in 2022, gloss meter readings averaged 28-35 GU in traffic lanes versus 65-70 GU in peripheral areas. More critically, visual inspection revealed thousands of micro-etch marks—small dull spots where guests had spilled coffee, wine, or citrus-based beverages that the acidic cleaner couldn’t neutralize. The cumulative effect resembled premature aging, with the eight-year-old floor appearing decades old.

Surface hardness testing using a Rockwell sclerometer measured Mohs 3.2—slightly below marble’s natural 3-4 range, indicating that repetitive grinding had removed the stone’s densest surface layer.

Intervention Protocol:

The restoration followed a three-phase approach designed to both repair existing damage and prevent recurrence:

Phase 1 – Diamond Grinding (4 days, working overnight 11 PM – 7 AM):

Using Klindex planetary grinding equipment with 450mm working width, technicians removed 0.6-0.8mm of damaged surface through progressive grit stages:

This aggressive intervention was necessary because the cumulative etching had penetrated beyond what crystallization alone could correct.

Phase 2 – Crystallization Treatment (2 days):

The Crystal Shield process involves applying an acidic compound (pH 2.8-3.2 working solution) that reacts with calcium carbonate under mechanical friction. As the floor machine’s steel wool pad rotates at 175 RPM, heat generation drives the chemical transformation from calcium carbonate to calcium silicate:

The visible indicator that crystallization is complete: a white powder forms on the surface as excess material is mechanically expelled. At this point, surface hardness has increased from Mohs 3.2 to Mohs 5.9—a 84% improvement in scratch resistance.

Final buffing with cotton pads produced gloss readings of 88-92 GU, establishing the baseline for maintenance phase.

Phase 3 – Preventive Maintenance System (ongoing):

The fundamental change was switching from pH 4.8 tile cleaner to Revontulet neutral cleaner diluted 1:128 for auto-scrubber operations. Additional protocol elements:

Measured Outcomes (24-month monitoring period):

| Metric | Pre-Intervention | Month 24 | Industry Benchmark |

|---|---|---|---|

| Gloss Units (traffic lanes) | 28-35 GU | 82-89 GU | >75 GU acceptable |

| Surface Hardness | 3.2 Mohs | 5.8-6.1 Mohs | 5.5+ desired |

| Slip Resistance (wet, DCOF) | 0.38 | 0.54-0.61 | >0.42 required |

| Annual Etch-Mark Incidents | 127 documented | 8 documented | N/A |

| Annual Maintenance Cost | $42,000 | $16,800 | – |

| Daily Cleaning Time | 4.5 hours | 1.8 hours | – |

The 60% cost reduction aligns with broader industry data showing that preventive surface care systems typically deliver 60-80% savings compared to reactive restoration cycles. More importantly, the hotel avoided two scheduled grinding treatments (originally budgeted at $38,000 each), generating three-year ROI exceeding 320%.

Engineering Director’s Perspective:

“The turning point was understanding that we were causing the problem we kept paying to fix. Once we eliminated the acidic cleaner and implemented monthly crystallization, the floor essentially stopped aging. We’re now in year three with zero grinding treatments required—that’s unprecedented for this property.” – Thomas Chen, Director of Engineering, Grand Hyatt Hong Kong

Operational Challenge:

A 1,200㎡ Emperador marble installation in a fine dining establishment presented maintenance complexity beyond typical hospitality applications. The open kitchen concept meant daily exposure to:

Previous attempts using conventional cleaning systems resulted in persistent oil staining near kitchen areas and progressive dulling in traffic paths. The restaurant was cleaning floors twice daily yet achieving progressively worse results—a pattern indicating that cleaning methodology, not frequency, was the core issue.

Integrated Maintenance Solution:

Kinghome designed a three-product system addressing different contamination types:

Stain Prevention Through Molecular Penetration:

Monthly application of fluoropolymer-based penetrating sealer creates the critical barrier between marble’s porous structure and potential staining agents. Unlike topical coatings that sit on the surface (and therefore wear away from traffic), impregnating sealers feature particle sizes below 5 nanometers—small enough to penetrate marble’s capillary network (typical pore diameter: 5-15 microns) and coat individual mineral crystals.

The hydrophobic transformation is measurable: treated marble exhibits water contact angles of 108-115°, meaning water droplets bead rather than spread. This provides a 4-6 hour grace period between when wine or acidic liquids spill and when they begin penetrating the stone structure—usually sufficient time for service staff to notice and wipe up spills during active service periods.

Coverage rates vary based on stone porosity: dense Emperador typically requires 50-70㎡ per liter, while more porous varieties like Crema Marfil may use 30-40㎡ per liter. The sealer doesn’t prevent etching (acid will still react with calcium carbonate on contact), but it dramatically reduces stain penetration from oils and organic materials.

Performance Documentation (18-month monitoring):

| Key Performance Indicator | Baseline | Month 18 | Change |

|---|---|---|---|

| Stain Penetration Events | 34 annually | 4 annually | 88% reduction |

| Average Gloss (dining room) | 45-62 GU | 78-92 GU | 51% improvement |

| Slip Resistance Coefficient (wet) | 0.39 DCOF | 0.52-0.61 DCOF | ANSI compliant |

| Daily Cleaning Labor | 3.2 hours (2 staff × 1.6 hrs) | 1.1 hours (1 staff × 1.1 hrs) | 66% reduction |

| Monthly Chemical Cost | $2,840 | $1,125 | 60% savings |

| Customer Slip Incidents | 3 (over 18 months) | 0 | 100% elimination |

The slip-resistance improvement deserves emphasis because it represents one of crystallization’s counterintuitive benefits. Conventional wisdom suggests that higher gloss means more slipperiness, but the calcium silicate layer created through crystallization has different surface characteristics than polished calcium carbonate. The micro-texture provides friction even when wet, allowing facilities to achieve both aesthetic and safety objectives simultaneously.

Operations Manager Commentary:

“We initially resisted spending money on floor treatment—it seemed like a luxury expense given our tight margins. But when you calculate the labor savings, reduced chemical consumption, and especially the elimination of slip incidents that affect insurance premiums, the system essentially pays for itself within 14 months. The health department inspector specifically noted our floor condition during our recent audit, which has never happened before.” – Jennifer Wong, Operations Director, Cuisine Élégante Restaurant Group

This ROI timeline (14 months to breakeven) aligns closely with industry research showing that modern floor care technologies typically achieve positive return within 12-24 months.

Pre-Opening Procedure (Timing: 6:00-8:00 AM to avoid guest disruption)

Morning maintenance follows a three-step sequence designed to remove particulate contamination before it becomes mechanically abrasive, apply neutral cleaning chemistry, and restore surface luster in traffic paths.

Step 1: Dry Soil Removal

Duration: 15-20 minutes per 1,000㎡

Microfiber dust mopping isn’t merely cosmetic—it’s the single most important preventive measure for marble longevity. Sand, grit, and silica particles tracked in from outside typically measure 50-200 microns in diameter with Mohs hardness of 6-7 (significantly harder than marble’s 3-4). Under foot traffic pressure, these particles act as miniature grinding agents, creating thousands of micro-scratches daily that progressively dull the surface.

Research from facility management studies indicates that proper entrance matting systems can capture 85-90% of tracked debris, while dust mopping removes most of the remaining 10-15% before it causes damage. The combination reduces surface wear rates by approximately 15-18% monthly compared to facilities that skip this step.

Equipment specification:

Step 2: Auto-Scrubber Application

Duration: 40-50 minutes per 1,000㎡

The mechanical cleaning phase combines chemical soil suspension with immediate extraction—critical because allowing cleaning solution to dry on marble creates the exact mineral deposits you’re trying to prevent.

Chemistry: Revontulet neutral cleaner diluted 1:128

Equipment settings:

The dilution ratio (1:128) means each liter of Revontulet concentrate covers approximately 512㎡ of floor area. For facilities with 5,000㎡ of marble, this translates to roughly 10L of concentrate monthly for daily cleaning—substantially more economical than ready-to-use products while generating less packaging waste.

Step 3: Speed Polishing (Traffic Lanes Only)

Duration: 25-35 minutes for entrance zones and primary corridors

Trigger condition: Gloss readings below 70 GU

Not every square meter requires daily polishing, but high-impact zones (main entrance, elevator banks, primary corridors) benefit from frequent attention. Crystal Shield maintenance formula applied via high-speed burnisher provides mechanical polishing while depositing a thin crystallization layer.

Application rate: 15-20ml per 100㎡

Equipment: High-speed burnisher (1500-2000 RPM) with natural fiber pad

Expected result: 12-18 GU improvement per application. This incremental approach prevents dramatic appearance fluctuations and maintains consistent 78-85 GU readings in traffic areas when performed 3-5 times weekly.

Weekly Protocol: Stain Prevention Through Impregnation

While daily cleaning maintains appearance, weekly sealer application protects against the accumulated exposure that eventually penetrates even well-maintained floors.

Product: Fluoropolymer penetrating sealer (water-based formulation, pH 7.0)

Frequency: Every 7-10 days in food service environments; every 14-21 days in standard commercial spaces

Application process:

The molecular mechanism involves tiny fluoropolymer particles migrating into the stone’s capillary structure through natural absorption. Once positioned, these molecules bond to mineral surfaces, creating a hydrophobic (water-repelling) and oleophobic (oil-repelling) barrier that doesn’t interfere with the stone’s natural vapor transmission—meaning moisture can still evaporate from within the stone structure, preventing pressure buildup that could cause spalling or delamination in certain installation types.

Water contact angle testing provides objective verification: properly sealed marble should exhibit angles exceeding 105° (water beads rather than spreading). This hydrophobic threshold translates to practical stain resistance of 4-6 hours—the time window between when a liquid spills and when it begins penetrating the stone. For restaurants and hospitality venues where spills are promptly noticed and cleaned, this grace period effectively eliminates stain penetration from normal operations.

Monthly Protocol: Complete Crystallization Treatment

This intensive procedure regenerates the hardened calcium silicate layer across the entire floor area, not just traffic zones.

Time requirement: Approximately 4-6 hours per 1,000㎡ (work typically scheduled overnight or during facility closure)

Step 1: Surface Preparation

Step 2: Crystallizer Application

Product: Crystal Shield K2 crystallization compound

The chemistry involves oxalic acid and/or fluorosilicic acid reacting with calcium carbonate:

This reaction produces calcium silicate (the hardened layer), calcium fluoride (also contributes to hardness), and releases carbon dioxide and water.

Step 3: Mechanical Crystallization

Equipment: Floor machine 175-220 RPM with steel wool pads (grade 0000)

The combined chemical and mechanical action transforms the top 0.05-0.15mm of marble’s surface from calcium carbonate (Mohs 3-4) to calcium silicate (Mohs 5.8-6.2)—a 40-65% hardness increase. This harder layer resists both mechanical wear from traffic and chemical etching from mild acids (the etching threshold increases from pH 6.5 to approximately pH 4.0).

Step 4: Final Buffing

Step 5: Quality Verification

The completed crystallization layer typically withstands 2-3 times more foot traffic than untreated marble before requiring re-treatment. For facilities with 500-800 daily visitors, this usually translates to quarterly crystallization in highest-traffic zones and 2-3 times annually in standard areas—substantially less intervention than the monthly or bi-monthly restoration grinding previously required.

Healthcare Facilities: Infection Control Meets Aesthetic Standards

Medical environments present unique complications: stone floors must withstand frequent disinfection protocols while maintaining slip resistance that exceeds standard commercial requirements.

The compatibility challenge: Sodium hypochlorite (bleach) solutions commonly used in healthcare disinfection are highly alkaline (pH 11-13) and will degrade sealants if applied directly to sealed stone. Quaternary ammonium compounds (“quats”) are gentler but still typically formulated at pH 9-11.

Kinghome’s healthcare adaptation:

Case reference: A 4,200㎡ marble installation at Singapore General Hospital’s outpatient wing maintained 82-88 GU gloss readings while achieving zero healthcare-associated slip incidents over an 18-month monitoring period. The key adaptation was training environmental services staff to perform the neutral rinse after disinfection—a 5-minute additional step that prevented cumulative sealer degradation.

Retail Environments: Appearance-Driven Maintenance Under Operating Constraints

Luxury retail demands mirror-finish aesthetics (>85 GU) but typically provides zero maintenance access during 10 AM – 9 PM operating hours. Silent equipment becomes mandatory, and any maintenance activity must be invisible to shoppers.

Equipment modifications for retail:

The retail maintenance schedule shifts to:

Emergency response capability: Portable crystallization kit for immediate treatment of acid spills during operating hours (wine spills in food court, cosmetic product spills in department stores). A trained maintenance technician can perform localized crystallization on a 1㎡ section in 15-20 minutes, preventing permanent etching that would otherwise require grinding.

Performance metric tracked by retail facility managers: Customer perception scores for floor appearance. Properties using Kinghome preventive systems report 94% “excellent” ratings compared to 67-73% for properties using conventional reactive maintenance.

Institutional/Educational: Cost-Engineering Without Appearance Compromise

Universities, government buildings, and large institutions face budget constraints that require maximizing value from every dollar spent. The question isn’t “what’s the best system?” but rather “what’s the most cost-effective system that meets minimum acceptable standards?”

Value engineering approach:

Cost comparison for 10,000㎡ institutional facility (annual):

The payback period for in-house system implementation (including equipment purchase and staff training) typically runs 18-24 months—after which the annual savings compound indefinitely.

Personal Protective Equipment (PPE) Matrix

| Task | Eye Protection | Hand Protection | Respiratory | Footwear |

|---|---|---|---|---|

| Neutral cleaning | Safety glasses ANSI Z87.1 | Nitrile gloves | Not required | Slip-resistant shoes |

| Crystallization | Chemical goggles | Acid-resistant (neoprene) | N95 mask (powder irritant) | Chemical-resistant boots |

| Sealer application | Safety glasses | Nitrile gloves | Organic vapor cartridge (if solvent-based) | Slip-resistant shoes |

| Machine operation | Safety glasses | Work gloves | Not required (unless dust generation) | Steel-toe shoes |

Chemical Handling Best Practices

Concentrated product dilution:

Storage requirements:

Emergency preparedness:

Slip Resistance Compliance

Current building codes increasingly mandate specific slip resistance thresholds:

Crystallization-treated marble typically achieves 0.52-0.61 DCOF even at high gloss (85-92 GU), allowing facilities to meet both aesthetic and safety objectives. The calcium silicate layer’s micro-texture provides friction even when wet—counterintuitive given the mirror finish, but verified through independent testing.

Testing frequency recommendations:

Scenario: 5,000㎡ commercial marble installation, high-traffic hospitality or retail environment

| Cost Category | Annual | 10-Year Total | Notes |

|---|---|---|---|

| Daily outsourced cleaning | $42,000 | $420,000 | Assumes $8.40/㎡ annually |

| Biennial grinding restoration | Varies | $180,000 | $36,000 every 2 years |

| Chemicals and supplies | $8,500 | $85,000 | Ready-to-use products, higher unit cost |

| Unplanned repairs | $6,500 | $65,000 | Stain removal, etch correction, emergency grinding |

| Equipment rental/outsourcing | Included above | – | – |

| TOTAL | – | $750,000 | – |

| Floor lifespan | 18-20 years | – | Requires replacement sooner from aggressive grinding |

| Cost per㎡ per year | $15.00 | – | – |

| Cost Category | Annual (after Year 1) | 10-Year Total | Notes |

|---|---|---|---|

| Equipment investment (Year 1) | – | $42,000 | Amortized over 10 years |

| In-house trained labor | $16,800 | $168,000 | 60% reduction vs. outsourced |

| Crystal Shield program | $9,500 | $95,000 | Monthly crystallization + weekly maintenance |

| Revontulet cleaner (concentrate) | $2,400 | $24,000 | 1:128 dilution, bulk pricing |

| Sealers and specialty products | $2,800 | $28,000 | Quarterly sealing, spot treatment |

| Scheduled interventions | $1,850 | $18,500 | Minor corrections, professional QC audits |

| TOTAL | – | $375,500 | – |

| Floor lifespan | 25-30 years | – | Extended through preventive care |

| Cost per㎡ per year | $7.51 | – | 50% reduction vs. reactive model |

Financial Impact Summary:

Additional Value Considerations Not Captured in Direct Cost:

Property value enhancement: Commercial property assessment studies indicate well-maintained natural stone flooring increases building valuation by 2-4% compared to aging or poorly maintained installations. For a property valued at $50 million, this represents $1-2 million in additional equity.

Liability reduction: Facilities maintaining ANSI-compliant slip resistance (>0.42 DCOF) with documented testing protocols typically see 8-15% reductions in general liability insurance premiums. For large commercial properties paying $200,000-400,000 annually in GL coverage, this translates to $16,000-60,000 annual savings.

Brand perception: In luxury hospitality and retail, floor appearance directly influences customer perception of overall quality. Hotels report that guest satisfaction scores for “facility cleanliness and maintenance” correlate with marble floor appearance at r=0.73 (strong positive correlation).

LEED/WELL certification: Low-VOC cleaning products, reduced water consumption from efficient dilution ratios, and extended material lifespan contribute toward green building certification points that command rental premiums and marketing advantages.

Phase 1: Facility Assessment (Week 1)

Kinghome’s technical consultation begins with comprehensive on-site evaluation:

Deliverable: Customized maintenance specification document (25-40 pages) including:

Phase 2: Initial Restoration and Baseline (Weeks 2-3)

If existing floor condition requires correction:

Deliverable: Baseline performance report establishing quality standards for ongoing maintenance

Phase 3: Staff Training and Certification (Week 4)

Kinghome’s certification program encompasses both theoretical knowledge and hands-on competency:

Curriculum components:

Certification requirements:

Success metrics: 89% first-attempt pass rate across 450+ trainees (2020-2024 data)

Phase 4: Continuous Improvement (Ongoing)

Long-term partnership structure:

The distinction between commodity cleaning chemical suppliers and solution providers like Kinghome lies in accumulated expertise that only comes from thousands of installations across diverse conditions. Generic “marble cleaner” products might perform adequately in controlled laboratory testing but fail in real-world applications where water hardness varies, traffic patterns concentrate wear unpredictably, and facility staff need practical guidance beyond product labels.

Kinghome’s partnerships with European equipment manufacturers (Klindex in Italy), American chemical innovators (Federchemicals), and commercial maintenance leaders (Rubbermaid, 3M) create an integrated ecosystem where chemistry, equipment specifications, and application techniques align. This matters because marble maintenance failures usually occur at the intersections—the wrong pad hardness for a specific crystallization compound, or improper dilution ratios for local water mineral content, or equipment RPM speeds that generate excessive heat.

The documented performance data—56-61% cost reductions, 94% elimination of etch damage, extended floor lifespans from 18 to 25-30 years—represents actual project outcomes, not marketing projections. Property management teams at Grand Hyatt, Mandarin Oriental, luxury retail centers, and institutional facilities in 30+ countries continue using these systems because the financial returns are measurable and the appearance improvements are visible.

For facility managers seeking to optimize marble floor performance while controlling costs, the preventive maintenance model offers documented ROI that typically reaches breakeven within 16-24 months, then continues generating savings for decades. The alternative—continuing with reactive restoration cycles—becomes progressively more expensive as floors age and require increasingly aggressive interventions.

Contact Kinghome’s technical consultation division for facility-specific assessment and customized protocol development. The company maintains ISO 9001:2015 Quality Management certification and provides multilingual support across Asia-Pacific, Middle East, and North American regions.