WELCOME TO KINGHOME

Get A Free Quote

We will get back to you within 8 hours

Concrete floor brushes are specialized cleaning attachments designed for floor scrubbing machines that remove dirt, stains, and buildup from concrete surfaces. Heavy-duty polypropylene brushes work best for rough, unfinished concrete due to their stiffness and chemical resistance, while softer nylon brushes are ideal for sealed or polished concrete to prevent surface damage. These brushes attach to disc or cylindrical scrubber systems and are essential for maintaining industrial, commercial, and hospitality facility floors.

Selecting the right concrete floor brush makes the difference between efficient cleaning and costly floor damage. Commercial property managers and facility maintenance teams face a critical decision: choosing brushes that provide effective cleaning power without degrading expensive concrete surfaces through excessive abrasion. The concrete floor brush attached to your floor scrubber system determines cleaning effectiveness, maintenance costs, and long-term floor integrity across warehouses, hotel lobbies, manufacturing plants, and retail spaces.

Understanding brush materials and configurations prevents surface damage while maximizing cleaning efficiency. The primary concrete scrubber brush types include:

These stiff, aggressive brushes excel on rough or textured concrete surfaces. Polypropylene bristles penetrate grout lines, broom-finished concrete, and uneven surfaces where debris accumulates in pores and crevices. The material’s inherent stiffness provides robust scrubbing action for removing embedded soils, while its chemical resistance withstands exposure to acidic cleaning agents. Polypropylene represents the most popular and cost-effective brush choice, typically shipped as standard equipment on commercial floor cleaning machines.

Nylon offers superior flexibility and bend recovery compared to polypropylene, making these brushes ideal for sealed, stained, or polished concrete floors. The softer bristles prevent scratching high-gloss finishes while maintaining excellent abrasion resistance that extends brush lifespan beyond polypropylene alternatives. Though more expensive upfront, nylon brushes last 50-75 hours of commercial use versus 30-50 hours for polypropylene. These brushes work effectively on diverse surfaces including wood, tile, laminate, marble, terrazzo, and delicate concrete finishes.

Designed for moderate to extreme duty applications, these specialized brushes feature nylon bristles coated with silicon carbide particles. The abrasive grit ratings range from 46 grit (extreme duty stripping) to 500 grit (fine polishing), allowing facility managers to match brush aggressiveness to soil severity. Light grit brushes remove heavy buildup and stains from terrazzo and non-slip epoxy, while heavy grit variants strip grease and grime embedded in concrete pores. These brushes typically last 30-60 hours depending on application intensity.

Disc brushes mount horizontally and spin at high speeds (approximately 300 RPM) to provide maximum downward pressure for removing scuff marks and stubborn stains on flat concrete surfaces. Cylindrical configurations feature counter-rotating horizontal brushes (600-800 RPM) that combine sweeping and scrubbing in a single pass, eliminating pre-sweeping requirements for debris-heavy environments. Cylindrical brushes reach into grout lines and textured surfaces more effectively than flat disc designs.

Matching brush selection to specific concrete floor finishes protects surfaces from premature wear while ensuring effective cleaning. The optimal concrete floor brush varies based on finish type, coating application, and usage environment.

| Concrete Floor Type | Recommended Brush Material | Bristle Characteristics | Primary Applications |

|---|---|---|---|

| Smooth troweled concrete | Medium polypropylene | Standard stiffness, 0.20″+ diameter | Warehouses, industrial spaces |

| Highly finished/polished concrete | Soft polypropylene or soft nylon | Small diameter (<0.20″), gentle action | Hotel lobbies, showrooms |

| Rough concrete (broom finish, exposed aggregate) | Stiff polypropylene or grit-coated nylon | Thick, aggressive bristles | Outdoor areas, parking garages |

| Stained/painted concrete | Soft polypropylene or soft nylon | Flexible, non-scratching | Retail spaces, offices |

| Resinous coated (epoxy, polyurethane) | Soft to medium polypropylene | Gentle to prevent coating wear | Manufacturing facilities |

| Unfinished industrial concrete | Heavy grit nylon (46-180 grit) | Silicon carbide coating | Food processing, heavy industry |

Standard polypropylene brushes provide consistent cleaning on smooth troweled concrete without etching or scarifying the low-roughness surface. These brushes handle everyday vehicle and pedestrian traffic soiling in warehouse environments effectively.

Concrete floors treated with mechanical polishing or clear sealant coatings require soft polypropylene with smaller bristle diameters (under 0.20 inches) or soft nylon alternatives. Using aggressive brushes on these surfaces removes gloss and damages the expensive finishing work within a few cleaning passes.

Broom-finished, exposed aggregate, and textured concrete surfaces demand thick, stiff polypropylene or carbide grit nylon brushes to penetrate surface irregularities. The bristle reach accesses dirt trapped in texture valleys that flat pads cannot address.

Epoxy and polyurethane resin coatings provide exceptional durability but remain sensitive to long-term mechanical scrubbing damage. Soft to medium polypropylene brushes prevent the micro-scratching that leads to coating breakdown, pocket failures, and expensive repairs. Pairing appropriate brushes with compatible professional floor cleaning chemicals extends coating lifespan significantly.

Implementing systematic maintenance protocols extends brush lifespan and maintains cleaning effectiveness. Proper care reduces replacement frequency and protects floor surfaces from damage caused by worn bristles.

Rinse brushes thoroughly after each use to remove cleaning solution residue, debris, and tangled materials. Trapped particles left overnight harden and create uneven bristle patterns that reduce cleaning efficiency and potentially scratch floors. Hang brushes to dry elevated off the floor, preventing bristle deformation from prolonged weight pressure.

Examine brushes for worn or flattened bristles that indicate approaching replacement needs. Check brush pressure settings on the scrubber machine, as excessive downward force accelerates bristle wear and floor surface damage. Rotate cylindrical brushes front-to-back weekly to counteract bristle bending and restore cleaning effectiveness. Multi-brush systems benefit from regular brush position rotation to ensure even wear patterns.

Replace disc brushes when bristles flatten or measure less than 3.2mm (1/8 inch) in length. Cylindrical brushes require replacement once bristles wear down to approximately 12.7mm (1/2 inch). Additional replacement signals include patchy bristle coverage from broken or missing bristle sections, reduced cleaning effectiveness requiring multiple passes, and visible floor streaking patterns.

Usage intensity and floor type determine optimal replacement timing:

Quarterly inspections and replacements represent industry best practice for facilities with daily cleaning schedules. Establishments with lighter usage should inspect monthly and replace based on bristle condition rather than time intervals alone.

New brush bristles exhibit maximum stiffness when first installed and soften during initial use. Protect floors by reducing scrubbing speed and downward pressure for 1-2 weeks while breaking in new brushes. This practice prevents surface damage from overly aggressive new bristles.

Concrete floor brushes serve diverse commercial, industrial, and hospitality environments with specific cleaning challenges.

Industrial facilities require heavy-duty polypropylene or grit brushes to remove stubborn grease, oil deposits, and heavy soiling from factory floors. These high-traffic environments accumulate debris that embeds in concrete pores, necessitating aggressive brushing action. Cylindrical brush systems eliminate pre-sweeping requirements by combining debris collection with scrubbing in a single pass, improving operational efficiency.

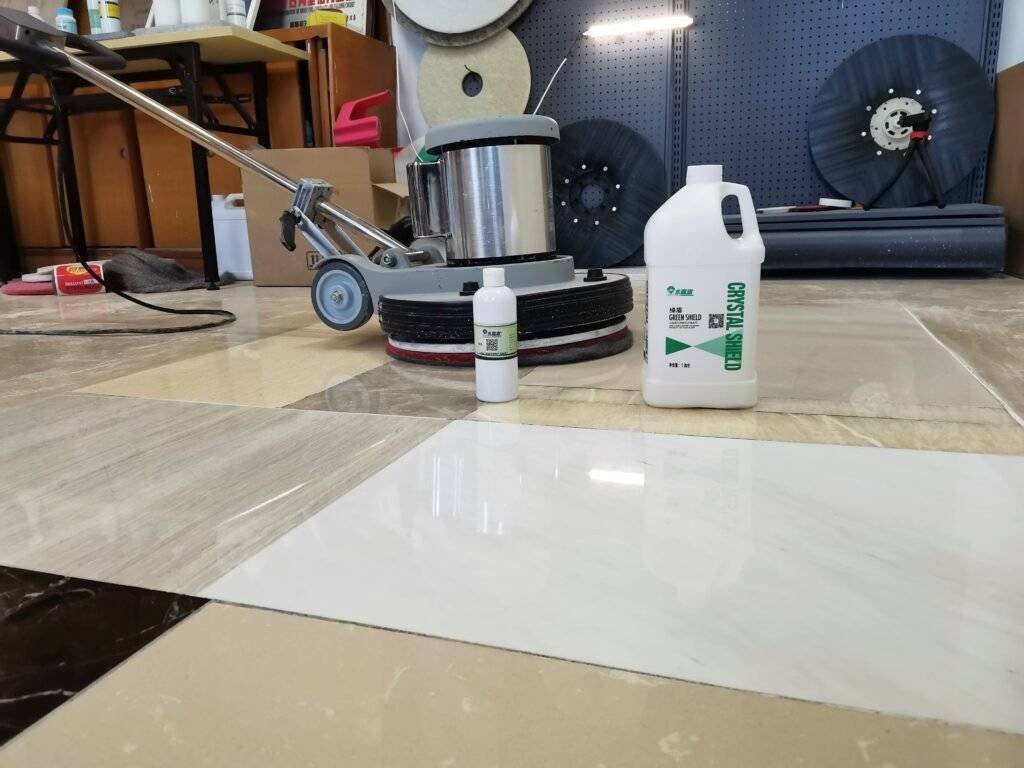

Hospitality facilities maintain polished or sealed concrete in high-traffic areas using soft nylon or polypropylene brushes paired with specialized concrete treatment solutions. The gentle cleaning action preserves high-gloss finishes while removing dirt, stains, and scuff marks from continuous foot traffic. Daily maintenance cleaning with appropriate brush selection maintains the premium aesthetic standards hospitality brands require.

Food service environments demand chemical-resistant polypropylene brushes that withstand acidic cleaning agents and meet stringent hygiene standards. These brushes remove organic matter, grease, and food residue from concrete floors while resisting degradation from frequent exposure to sanitizing chemicals. The material’s non-absorbent properties prevent bacterial growth within bristles between cleaning cycles.

High-traffic retail environments benefit from daily maintenance cleaning using standard polypropylene disc brushes on walk-behind scrubber systems. These brushes efficiently remove daily soil accumulation, beverage spills, and tracked-in debris across large floor areas. The balance between cleaning effectiveness and floor protection suits the mixed concrete finishes common in retail applications.

Post-construction cleaning requires the most aggressive brush options—heavy grit nylon or metallic wire brushes—to remove concrete residue, dried mortar, and construction debris. Wire brushes intentionally scarify and strip embedded soils, though they leave surface scratches and should only be deployed in heavy industrial and outdoor environments where surface aesthetics are secondary to aggressive cleaning.

Optimal cleaning results require pairing appropriate concrete floor brushes with professional floor cleaning machines and equipment designed for commercial stone and hard surface maintenance. Modern high-pressure floor scrubber systems incorporate adjustable brush pressure controls and variable RPM settings that facility managers calibrate to specific concrete floor types.

Understanding material property differences guides purchasing decisions based on budget constraints, floor sensitivity, and expected brush lifespan.

| Property | Polypropylene (Black Poly) | Nylon |

|---|---|---|

| Cost | Lower upfront investment | 20-40% more expensive |

| Durability (hours) | 30-50 hours commercial use | 50-75 hours commercial use |

| Stiffness | Higher stiffness for aggressive scrubbing | Superior flexibility, better bend recovery |

| Water absorption | Zero absorption (ideal for wet cleaning) | Minimal moisture absorption |

| Chemical resistance | Excellent, especially acidic environments | Good resistance to most cleaners |

| Surface compatibility | Rough, unfinished, textured concrete | Sealed, polished, high-gloss finishes |

| Abrasion resistance | Moderate, bristles wear faster | Superior abrasion resistance |

| Best applications | Daily warehouse cleaning, grout lines, industrial floors | Hotel lobbies, terrazzo, marble, delicate concrete |

The material’s lower cost makes polypropylene ideal for high-frequency cleaning operations where brushes require replacement every 30-50 hours. The complete absence of water absorption maintains consistent bristle stiffness throughout wet cleaning applications without softening. Chemical resistance surpasses nylon for facilities using acidic concrete cleaners or aggressive stripping solutions. Standard polypropylene brushes ship with most commercial floor scrubbers due to their versatile all-around applicability.

Superior abrasion resistance delivers 40-50% longer lifespan than polypropylene, reducing replacement frequency and long-term costs despite higher purchase prices. Excellent flexibility and bend recovery maintain bristle shape and cleaning effectiveness longer than stiffer alternatives. The material’s gentleness on delicate surfaces prevents scratching sealed or polished concrete finishes. Nylon’s durability makes it cost-effective for facilities prioritizing brush longevity over initial investment.

Polypropylene offers lower upfront costs suitable for budget-conscious operations accepting more frequent replacements. Nylon’s extended lifespan delivers better total cost of ownership for facilities with premium flooring requiring gentle cleaning action. High-volume operations cleaning rough industrial concrete favor polypropylene’s aggressive action and affordable replacement cycle, while low-volume facilities maintaining polished concrete benefit from nylon’s longevity and surface protection.

Concrete floor brush selection directly impacts cleaning effectiveness, operational costs, and floor surface longevity across commercial and industrial facilities. Polypropylene brushes deliver aggressive, cost-effective cleaning for rough and unfinished concrete, while nylon variants provide gentler action that protects sealed and polished surfaces. Implementing proper maintenance protocols—daily rinsing, weekly inspections, and timely replacement when bristles reach 3.2mm length—maximizes brush lifespan and prevents floor damage.

Facility managers should match brush material and grit rating to specific concrete floor finishes, adjusting from soft nylon for high-gloss lobbies to heavy carbide grit for industrial warehouses. Regular brush rotation, appropriate scrubber pressure settings, and integration with compatible cleaning solutions create comprehensive maintenance programs that reduce total cost of ownership.

Browse professional floor brush options designed for commercial concrete cleaning applications, or explore specialized concrete floor protection solutions that extend surface lifespan between deep cleaning cycles.