WELCOME TO KINGHOME

Get A Free Quote

We will get back to you within 8 hours

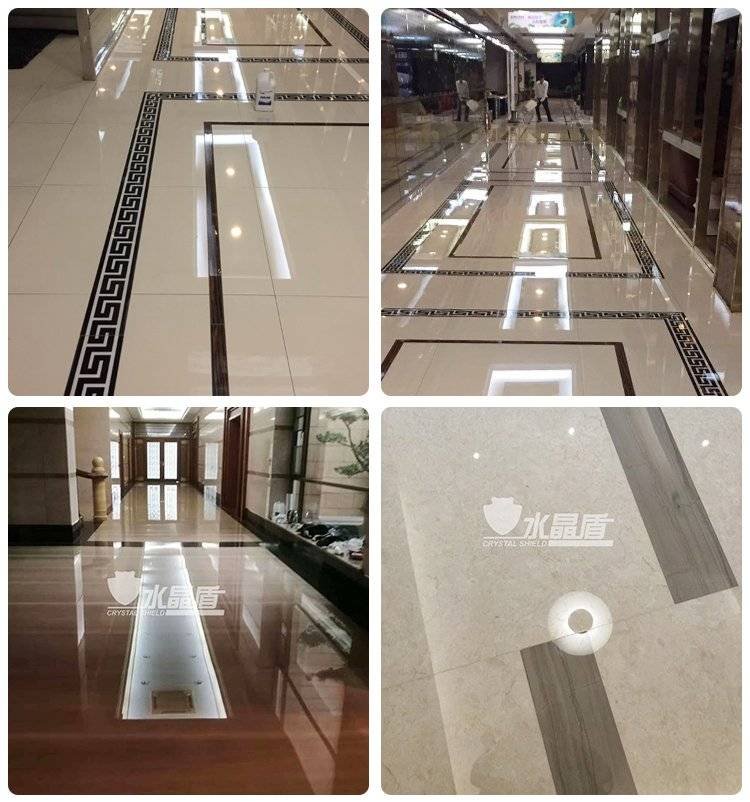

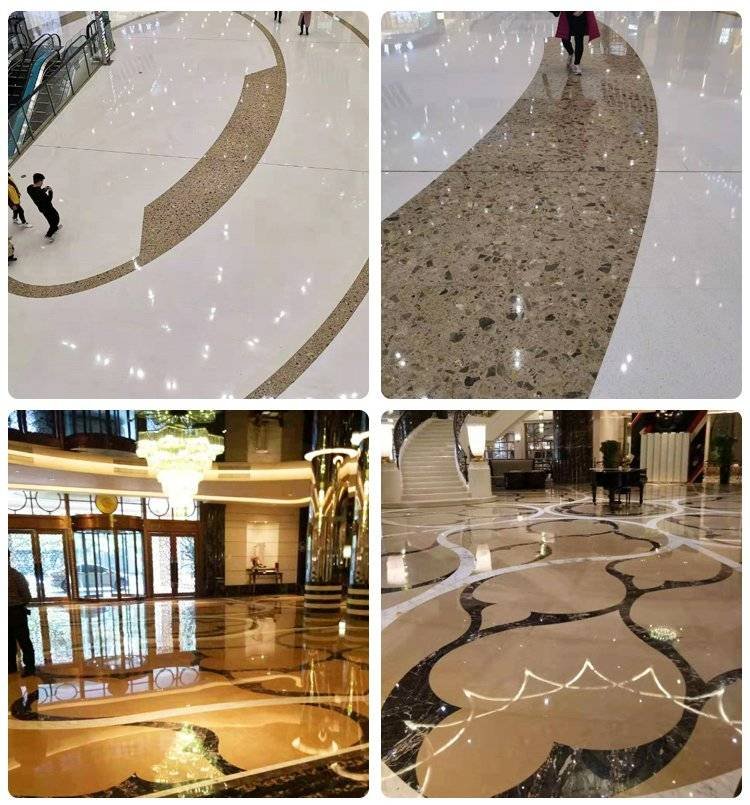

Stone crystal plating and crystallization are two core surface protection and beautification processes for stone. Though differing by just one word, they vary significantly in technical principles, protection effects, applicable scenarios—especially for short-term optimization versus long-term protection in stone maintenance. Today, we compare them across 7 key dimensions with real-world application advice, helping you master the differences for smarter future stone care choices.

The fundamental difference lies in how each process affects the stone surface:

Crystallization Treatment:

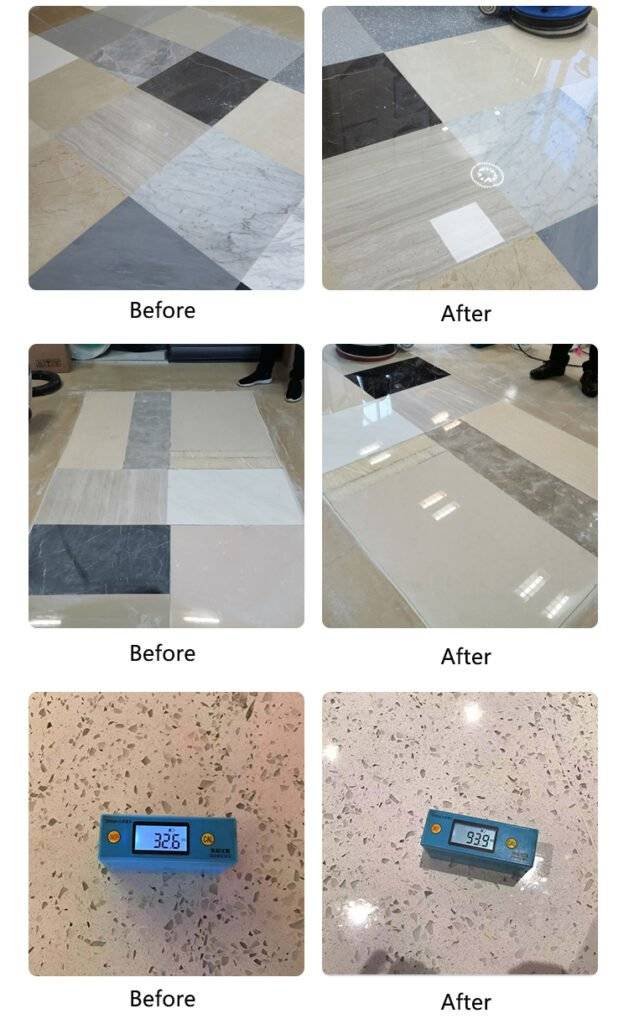

A “physical hardening + surface optimization” process. Specialized crystallizing agents (mainly fluoro silicate and organic acids) react chemically with minerals on stone surfaces (especially carbonate stones like marble and limestone), forming a hard microcrystalline glass layer (typically 5-10μm thick). High-speed polishing machine friction heat fuses this layer with the stone, filling micro-pores and boosting hardness.

In simple terms: Activates the stone’s own surface minerals to create a new hardened layer, without adding extra coverage.

Crystal Plating Treatment:

A “chemical coating + sealing protection” process. Specialized plating agents (mainly nano-silica (SiO₂) and siloxanes) form a transparent, dense polymer protective film on the stone (20-50μm thick). This independent film bonds via chemical keys, acting like “transparent armor” to block external contaminants.

In simple terms: Adds an artificial synthetic protective film on top, focusing on “sealing” rather than hardening the stone itself.

| Comparison Dimension | Crystallization Treatment | Crystal Plating Treatment |

|---|---|---|

| Surface Hardness | Significant boost (marble from Mohs 3-4 to 5-6), strong scratch resistance | Medium film hardness (Mohs 4-5), scratch resistance relies on thickness, inferior to crystallization |

| Protection Ability | Basic: Mild water/stain resistance, can’t block oily/pigment stains (coffee, soy sauce) | Comprehensive: Water-repellent (>110° contact angle), oil/stain/UV resistant (some with UV blockers), blocks stubborn stains |

| Gloss Level | High shine (80-90°), natural “stone glow” | Medium (60-80°), “filmy mirror shine,” some feel artificially slick |

| Film Durability | Short-term: 3-6 months indoors dry, 1-3 months high-traffic, needs regular reapplication | Long-term: 1-3 years indoors, 6-12 months outdoors (UV-resistant), 3-10x longer than crystallization |

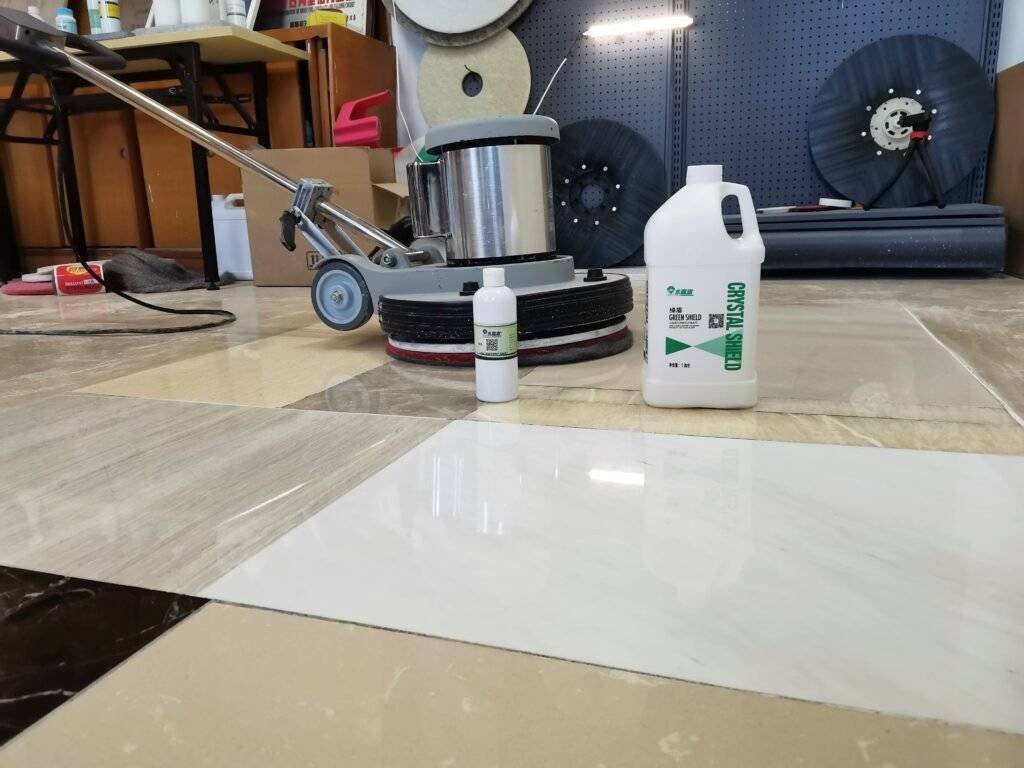

| Application Difficulty | High: Relies on technician skill, precise polishing speed (1500-2500 RPM), pressure, agent amount—risk of “burning” (yellowing) | Medium: Standardized (clean → dewax → plate → cure), no heat/pressure, beginner-friendly if base is clean |

| Repair Ease | Local wear fixable locally (re-polish), but may show gloss mismatch needing full blend | Local damage requires full strip and re-plate (no spot fixes), high repair cost |

| Applicable Stone Types | Carbonates only (marble, limestone, travertine); silicates like granite react poorly | Universal: Marble, granite, quartz, tiles, microcrystal stone, all stone/tile bases |

Process differences directly impact timeline, cost, and result consistency:

Key Challenge: Uneven pressure causes inconsistent layer; high speed risks “burning” (yellowing/carbonization).

Key Challenge: Incomplete base cleaning (residual oil/water) causes peeling; uneven application leaves “water marks.”

Scenario differences stem from matching “priority needs”:

Typical Scenarios:

Typical Scenarios:

From one-time and lifecycle costs, each has pros/cons:

Crystallization:

Crystal Plating:

Misconception 1: “Crystallization is shinier than plating, so better”

Crystallization shine is the stone’s natural warm glow; plating is filmy mirror gloss (colder/harder). It’s a texture difference, not quality—choose by scenario (hotels: warm shine via crystallization; kitchens: easy-clean via plating).

Misconception 2: “Plating replaces crystallization in one step”

Plating focuses on protection, not hardness boost. For soft marble, damaged plating exposes scratches; do crystallization first for hardness, then plating for seal (“crystallization + plating” combo for high-value stone).

Misconception 3: “Granite can be crystallized”

Crystallizers react with carbonates; granite’s silica (silicate) doesn’t react—forced crystallization dulls/mats it. Granite needs plating only.

By Stone Type:

By Usage Scenario:

Conclusion:

Crystallization optimizes surface hardening for short-term shine + durability; crystal plating provides film protection for long-term stain resistance + low upkeep. No absolute winner—match to stone traits and needs.